top of page

Gear Reducer

The Situation

I was tasked with designing a gear transmission to transmit motion and torque through three shafts with a designated speed reduction.

The Task

The gear train system needed to reduce a motor outputting 2400 RPM and 15 kW of power through one intermediary shaft to a third shaft rotating between 330 and 350 RPM. The transmission also needed to have a 5 year work life.

The Process

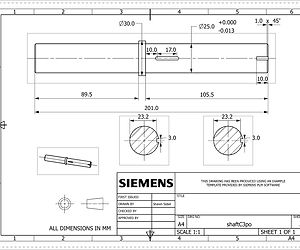

From these guidelines, I performed stress

analysis and material selection for shafts,

bearings, and gears. This data was then

used to create a working assembly in NX.

The Results

At conclusion, the gear reducer successfully

fulfilled all requirements and withstood

all theoretical sample stresses.

bottom of page